About Us

In recent decades, a growing number of distilleries, wineries and liquor companies begin to value bottle stoppers as a means of adding greater prestige and personalization to their packaging.

In response to the growing demand for personalized packaging solutions, ASTRID PACKAGING offers a variety of stopper solutions with expertise in premium bottle stoppers that are both functional and artistic: crystal glass, wood, metal, zamak, ceramic, plastic, aluminum, acrylic, etc.

Through drawing design, mold casting, raw material selection, manual molding, polishing, manual cleaning, quality inspection and screening, ideas and imaginations are made into final products

Why Choose Us

Rich Experiences

Over 10 years of experience and knowledge in liquor packaging industry. Our clients can easily personalize their premium stoppers by choosing components.

Artistic Products

Expertise in premium bottle stoppers that are both functional and artistic: crystal glass, wood, metal, zamak, ceramic, plastic, acrylic. You can choose anything you want.

Patent Structures

ASRTID created innovative patent structures for bottle stoppers which prevent any risk of cork falling off. We know how important this is to you, so we take extra care to this aspect.

Technical Team

Our technical team has developed 18 categories and more than 1500 models/sizes. That wide range of models could cover most bottleneck sizes and meet most clients’ needs.

Support Customization

Personalize easily. After selecting the size of cork, customers then select different materials and elements for the top for the top, bottom, ring, medallion and topside.

Free Packaging Solution

Packaging is an important part of brand success. We aim to help all clients find the best packaging solution, build up their brand image and increase the volume of sales through delicate packaging.

Crystal Glass Bottle Stopper

Plastic Bottle Stopper

Solution

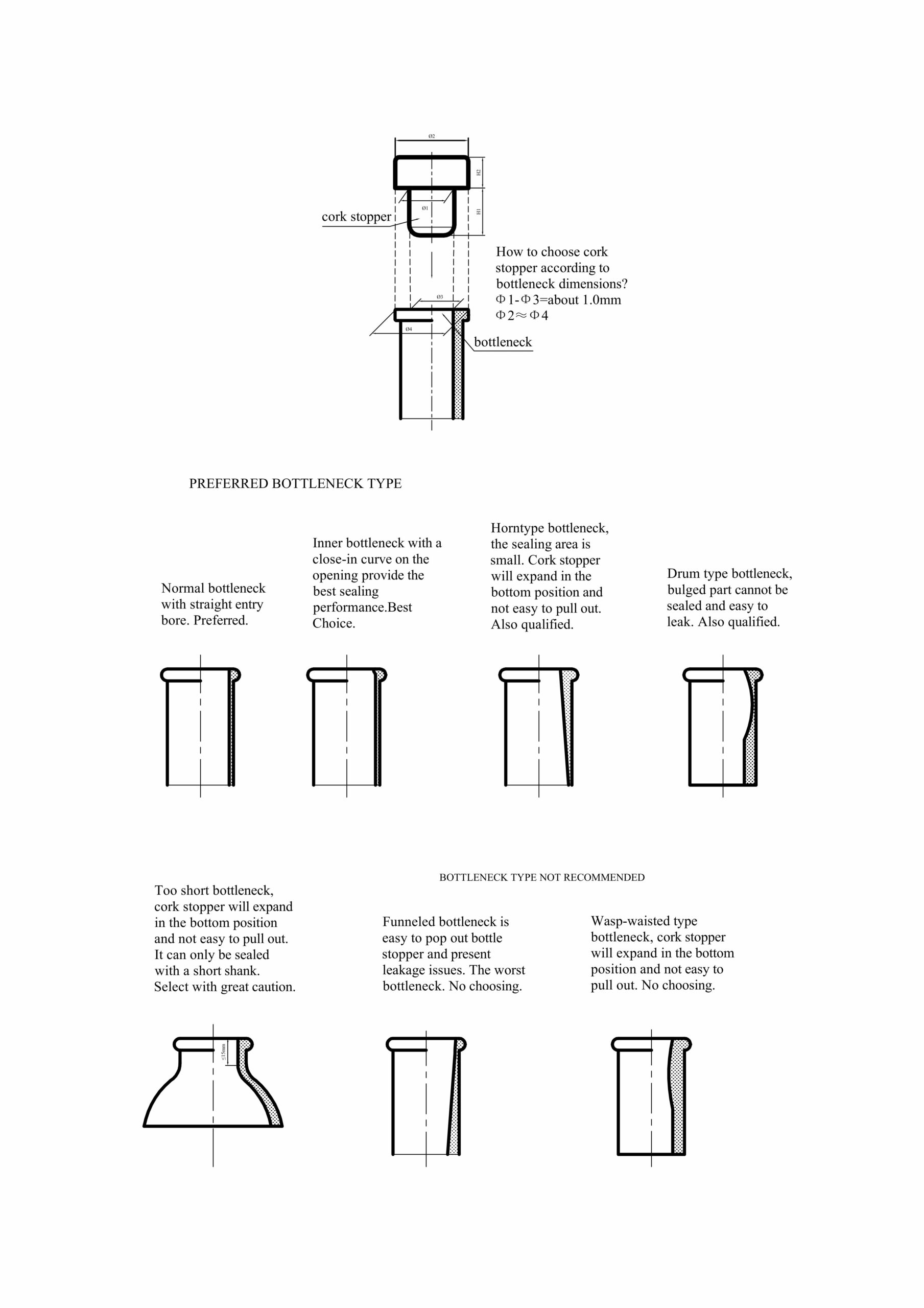

1. How to prevent leakage?

Check the shape of entry bore before choosing a bottle.

How to do this?

Use an Inner groove vernier caliper

Still not sure about the shape of the bottleneck? Talk to Grace now!

2. What to do When you already purchased a batch of bottles and bottle stoppers that present leakage problems, and you have absolutely no idea why?

About Bottle

Step 1: check the shape of the entry bore. (see solution 1) If the inner bottleneck shape is bad, but the bottle is expensive, turn to Step 2.

Step 2: Our engineer will make customized mould for corks based on the shape of the bottleneck, to prevent leaking.

About Weather

Certain types of liquor release gas during transport, especially in summer. This will pop the plug out and lead to leakage problems. Businesses need to avoid sea transport during hot seasons and carry out tests before mass production.

About Cork

Natural corks are conventional choices for most businesses. When applied and stored well, they are great components of liquor packaging. However, natural corks can get moldy, broken or have debris. In these cases, synthetic corks are an excellent substitute.

The Characteristics of synthetic cork:

1. Sealing completely and tightly, keeping original flavor of wine and liquid.

2. Never to be broken, size is consistent and unify.

3. Keep free from contamination, Moisture and mildew.

4. Food grade and odorless.

3. How do we know whether the bottle stopper is suitable to the bottle or not?

(1)Most bottles are used to contain liquid. In the filling process, the liquid will wet the bottleneck.

(2)After we receive bottle stopper samples, we need to wet the bottleneck(or wet the stopper), then try to insert the bottle stopper to the bottle. You will feel it neither too tight nor too loose, and will need certain strength to pull out the stopper.

(3)Then please fill the bottle with spirits /diffuser (depends on your product) and do not fill it too full. If you fill the bottle too full, the air pressure will be very high inside the bottle. The stopper will be easy to pop out. Usually, the liquor should be filled according to specified volume. (For example, 700ml)

Then you lay the bottle flat on a piece of white paper. Wait till the next day to see if there is any leaking or popping out. (if it leaks, the white paper will wrinkle.) If not, then the stopper is suitable for this bottle. Then you can go on to step 4.

(4)If condition permits, lay the bottle flat inside a car and drive for a few days to check if there is any leaking or popping out.

After step 3, place the bottle upright on the table and leave it for 3~5 days. After the bottle stopper dries out, pull out the stopper. If the stopper is too tight and get stuck in the bottleneck, impossible to pull out, then this bottle stopper is not the right size for this bottle. We need to choose other models. If you can pull it out successfully, then it is the right size for your bottle.

ATTENTION! The cork material cannot be used at high temperatures.

Our Clients

Brand that trust ASTRID.

Want to Talk About Your Project?

Order a sample pack so you can feel our premium range of bottle stopper for yourself.